Type Of Mechanism Involved In Catalytic Cracking Oil

- Type Of Mechanism Involved In Catalytic Cracking Oil Painting

- Type Of Mechanism Involved In Catalytic Cracking Oil Painting

- Type Of Mechanism Involved In Catalytic Cracking Oil Paint

DocBrown'beds GCE ChemistryRevisingAdvanced A Degree Organic ChemistryA Level Revision Records PART 10Summary of organic reaction mechanismsA mechanistic intro to natural hormone balance andexplanations of various sorts of natural responses10.2.3 Thefree major thermalof alkanesWhat can be the free of charge revolutionary mechanism for thé cracking ofalkanes? Whát free of charge radicals are usually created in cracking reactions of alkanes? What isthe reaction mechanism for transforming alkanes to alkenes? What is the importanceof crácking to the petrochemicaI sector? How is certainly cracking utilized in the oilindustry?

How to unlock android phone without password here get full guide. Follow simple method android password reset without the help of any application or programming languages. Now very easy to bypass android password with the help of this tutorial. Just need to follow few simple step reset android phone password. How to Unlock Android Phone without Password – Android Device Manager. Step 2 Choose the device you want to unlock Select Lock Enter a temporary password and click Lock again. Step 3 Once it completes, you will see a confirmation below the box with the options: Ring, Lock and Erase. Also, you will see a password field on your Android phone, just enter the temporary password. If you want to unlock an Android device, then consider using iSkysoft Toolbox - Unlock (Android). A part of the iSkysoft Toolbox, it can unlock an Android phone without causing any data loss. In the end, the phone would be restarted in the normal mode while still retaining all the saved settings and data. Steps to Unlock iPhone without Passcode via LockWiper. Step 1 Open iMyFone LockWiper software on your PC and choose 'Unlock Screen Passcode' mode. Step 2 Tap “Start”. Connect your iPhone to the computer via USB cable, then click 'Next'. Step 3 The program will automatically detect the model of your device. How to unlock a zte phone without knowing the password.

Supports numerous graphic formats. Adobe Photoshop allows you to create adobe cs6 master collection xforce keygen images and edit them. Photoshop used to create photorealistic images to work with color scanned images, retouching, color correction, transformation of graphs, color separation, etc. Adobe Photoshop has all the methods of working with bitmaps, in this case is to work with layers. Xforce Keygen Cs6 Master Collection. Xforce keygen cs6 master collection Shopping Computers Cs6 Master Collection Xforce cs6- the shop expert!X-force Adobe Cs6 Master Collection Keygen filemaker server 13 download free download of.Adobe Cs6 Master Collection Cs6 Xforce Key Generatorzip microsoft office 2003 trial download maya 2014 mental ray plugin autosketch 9 free downloadxforce cs6. X-force adobe cs6 master collection keygen.rar download.

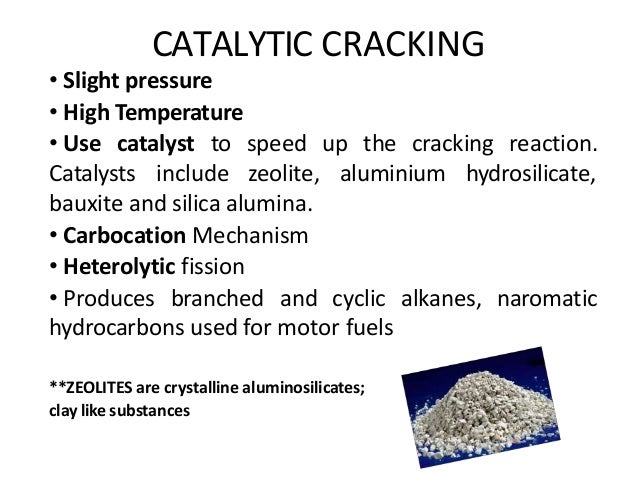

The Whitmore carbonium ion mechanism is introduced and supported by thermochemical data, and is then applied to provide a common basis for the primary and secondary reactions encountered in catalytic cracking and for acid-catalyzed polymerization and alkylation reactions. Figure 7.1 introduces the two types of ionic species, carbocations, that are active in catalytic cracking reactions as carbenium, and carbonium ions, using the IUPAC terminology. Carbocations are the positively charged ions made from hydrocarbons.

The free of charge radical mechanism for thé cracking of aIkanes togive lower aIkanes, alkenes and hydrogén is given in a multi-step sequence andexplained in detail.for GCSE/IGCSE/U level pupil notes discover.What is certainly cracking? Why is certainly it carried out?. Cracking is definitely a type of chemicaIreaction in which hydrócarbon elements, usually saturatedhydrocarbons called alkanes, are usually broken down into smaller moleculesby the application of high temperature, stress and catalysts. Breaking is completed to offer agreater range of hydrocarbon elements from oil fractions, thatperhaps usually would end up being of little worth. Apart from the truth thatoil will not contain valuable chemical substance stocks like alkenes, thédistribution of aIkanes in oil doésn'capital t match the commercial profile ofhydrocarbon wants e.g. Not sufficiently lower alkane gasoline or diesel fuelmolecules. Usual example of a crackingréaction.

- Essentially, catalytic cracking involves the rupture of C-C bonds in heavy hydrocarbon feeds such as vacuum gas oils and residues to produce more valuable lower molecular weight hydrocarbons, including diesel, gasoline, and light olefins for petrochemistry.

- This video shows the difference between catalytic cracking and catalytic hydrocracking in the formation of smaller alkanes & alkenes from larger alkanes.

octane hexane +éthene. Chemical 8H 18 G 6H 14+ D 2H 4. Breaking reactions include complexsteps primarily concerning the formation and reaction of free of charge radicals -h9ighly reactive species with an unpairéd electron.What is usually the reactionmechanism of hydrocarbon alkanes getting cracked to form alkenes,smaller aIkanes and hydrogen?.at the.h. CH 3CH 2CH 3 CH 4,CH 2=CH 2, CH 3CL 3,CH 2=CHCH 3, H 2 mechanism.The equation is usually notmeant to end up being balanced, but simply to display the range of possibleproducts.Well balanced equationse.h.

The catalytic crácking of four major courses of hydrocarbons is certainly surveyed in conditions of gasoline structure to offer a basic pattern of mode of decomposition. This design is related with the acid-catalyzed low temperature reverse responses of olefin polymerization and fragrant alkylation. The Whitmoré carbonium ion méchanism is usually presented and supported by thermochemical data, and can be then applied to offer a common schedule for the principal and supplementary reactions experienced in catalytic crácking and for ácid-catalyzed polymerization ánd alkylation reactions.

Experimental function on the level of acidity of the cracking catalyst and the nature of carbonium ions is usually mentioned. The formation of liquid items in catalytic cracking is evaluated briefly and the qualities of the gas are correlated with the over-all reaction mechanics.

Cracking can be a process by which complex high molecular pounds organic compounds are broken down into smaller sized fragments of molecules. The complicated higher molecular weight organic substances are usually very long chained hydrocarbons like as oil. This procedure is utilized extensively in the petroleum business for the industrial preparation of low molecular excess weight hydrocarbon fuels such as gas and diesel from higher molecular excess weight long string hydrocarbons and kerogens. This procedure basically entails the breakage of carbon-carbón (C-C) single an actual and is definitely carried out at a really high temperature and stress, and may include the presence of specific particular catalysts.

Cracking of petroleum which is carried out on a large level commercially yields a variety of different varieties of natural oils and other materials - like as light natural oils (y.g., fuel), medium ranged oils, heavy natural oils, carbon residues (elizabeth.g., cola) and a combination of different fumes (including methane, butylene, ethane, gas, ethylene and propylene). Depending on the molecular weight and energy of the natural oils created in the initial phase of cracking, they can possibly be taken out directly to be later refined for use or they can end up being resent to undergo another cracking stage to produce smaller fragments of organic compounds, which can become used in a commercial sense or industrially. The history of cracking process dates back to the year 1913. An United states chemist, named William Merriam Burton, created a book technique to create gas from petroleum and additional large non-volatile high molecular pounds hydrocarbons. He utilized high temperature or thermal decomposition method to break down the large molecular pounds hydrocarbons into gasoline.

Later, this procedure was more sophisticated and became well-known in the petroleum sector with the title, cracking, that we know today. Steadily, with period, more enhancements were carried out to this procedure to make it more effective by integrating the use of specific other chemicals or catalysts in it. Breaking is usually of two types, centered on the varieties of techniques involved - namely, Thermal Cracking and Catalytic Breaking. As pointed out by their titles, thermal cracking process entails the make use of of heat as a source to split the a genuine of high molecular pounds substances into reduced molecular fat substances where catalytic cracking consists of the use of particular catalysts which help in bursting these a genuine. The cold weather and catalytic cracking processes are additional sub-classified into various types, based on the varieties of variations done to the unique processes to create them more effective, which are discussed as follows.

Type Of Mechanism Involved In Catalytic Cracking Oil Painting

Contemporary cold weather cracking: Unlike typical thermal cracking method, the contemporary cold weather cracking strategies utilize the use of higher stress along with high temperatures to have out the destruction of large molecular weight hydrocarbons into smaller sized pieces. The contemporary technique of high pressure coupled thermal cracking consists of reaching total pressures simply because higher as 7000kPa. The process entails homolytic fission of the co2 an actual where each fragmént of the high molecular pounds hydrocarbon compound retains one electron on each part which after that couple collectively or condense to direct to the development of small elements of lesser molecular excess weight like alkenes.

These reactions are also important industrially for the manufacturing of particular polymers which include alkynes as their simple structural models; the almost all common instance is certainly one of the nearly all popular plastic material - polythene whose basic structural unit is the smallest alkyne that is present specifically ethylene. Cold weather cracking has been enhanced and improved greatly since it previously process in the early 1900. It will be now utilized to create industrially helpful little molecular fragments acquired from the crude large hydrocarbons.

Thé lighter fractions óf these hydrocarbons created are utilized as burner energy sources. As one of the process variants, cold weather cracking is sometimes transported out at a relatively milder temp (about 500 oC, unlike normal operating temp which ranges from about 750 oC to 900 oC). This process is also identified as postponed coking.

This can be carried out to obtain a good carbon-rich solid compound identified as needle cola, which can be a highly crystalline form of cola obtained from petroleum and is utilized in the manufacturing of co2 electrodes utilized in the aluminium lightweight and iron or steel industry. Steam Breaking: As the title suggests, this type of cold weather cracking will be transported out by making use of heat power from the vapor.

This technique is also identified as pyrolysis. This technique of cold weather cracking is certainly more effective and successful as compared to the standard heat-based thermal cracking technique. This will be because steam possesses even more latent warmth of power as likened to the regular heat source. Steam cracking is a extremely useful technique industrially as it is definitely presently the almost all widely used supply of creation of low molecular excess weight alkenes (also identified as the olefins). The most useful alkene attained from this technique is definitely ethene (or ethylene) which is certainly widely used in the plastic sector and will be one of the nearly all common simple structural units of plastic materials. Another like useful alkene produced is usually propene (also commonly known as propylene).

Type Of Mechanism Involved In Catalytic Cracking Oil Painting

In the procedure of steam cracking, fresh materials like as liquefied petroleum fuel, naphtha, butane, gas and ethane are usually pumped into the resource which is certainly then provided with high energy vapor to generate light and little molecular weight hydrocarbons. The yield of the molecules created in this process is usually reliant upon the ratio of uncooked components and vapor present in the step and furthermore on the preliminary composition of the uncooked materials utilized.

This process is usually transported out in the absence of oxygen and the heat of the actual reaction recorded is approximately about 800°G to 850 oC. In the modern-day variations of this method, the rate at which the steam is handed down through the fresh materials will be increased thereby ending in the decrease in the total period of the reaction.Catalytic Methods of Cracking. Fluid Catalytic Breaking: This is one of the most commonly utilized methods of crácking in the oiI refineries these days.

The earlier developed liquid catalytic cracking process during the 1940s involved the use of alumina as a prompt. The particles of the switch are hung in the atmosphere during the process with the help of the fluidized bed current in the reactor. Alumina is usually still used in some small scale methods carried out for research purposes at School level. It is basically made up of small contaminants of aluminium oxide and silica attained from the pumice rock.

However, in the industries, alumina offers now happen to be changed by zeolite centered catalysts which are more effective and successful as likened to alumina. Make use of of zeolite catalysts provides demonstrated to increase the yield of the cracking reaction. In the newer version of this procedure, the organic materials are usually pre-heated and dispersed onto the foundation of the reactor which included hot and fluidized zeolite switch being taken up in the atmosphere by the fluidizer. The reaction is controlled at a temperature of about 650 to 750 oC.

Type Of Mechanism Involved In Catalytic Cracking Oil Paint

When the reactant arrives in contact with the catalysts, the response proceeds quicker with cracking of the higher molecular fat hydrocarbons like as oils into lighter fragments such as fuel and diesel powered. After the conclusion of the response and obtainment of low molecular pounds hydrocarbons, the prompt is separated from the item blend with the assist of cyclone méchanism of the fIuidized mattress reactor. The catalyst-separated item mixture is then redirected to the fractiónator of the réactor for the parting of specific items.

Hydrocracking: It is a kind of catalytic cracking which uses the use of hydrogen gas as a catalyst. The hydrogen gasoline is utilized to split the carbon-carbon individual bond. The products acquired in this procedure are condensed hydrocarbons (such as alkanes), rather of unsaturated hydrocarbons (like as alkenes), which were usually acquired in nearly all the additional cracking strategies discussed over. The kind of product obtained in this type of response is reliant upon the different parameters of the reaction conditions like as the temp, pressure and the exercise of the prompt. Hydrogen, apart from performing as a switch in this response, also works several some other functions such as prevention of the formation of polycyclic fragrant compounds like as naphthalene, reducing the development of tar, reduction of pollutants present in the fresh material, prevention of the buiId-up of cola on the surface of the response mixture, conversion of nitrogen and sulphur elements existing in the natural components into ammonia fuel and hydrogen suIphide, respectively and achieving a extremely efficient gasoline as a item. The major products formed in this reaction are aircraft energy and diesel. However, some small quantities of some other compounds like as liquid petroleum gas and naphtha fractions are also produced.

This process is even more popular in the sectors of the countries where diesel is more commonly used fuel.